Microstructure Control in Metal AM

Combining Geometry and Microstructure Complexity

Beyond manufacturing of parts with complex geometry, metal additive manufacturing is inspiring new designs of materials with heterogeneous, architected microstructures. Using laser powder bed fusion (LPBF), for example, it is possible to change the local conditions that drive solidification of the material by tuning the laser parameters and induce the formation of microstructures with different grain size, phases, crystal orientation, and grain boundary character distribution. Following this strategy, a single component may therefore be designed with complex geometry and multiple distinct microstructures, each chosen to best suit the constraints at a given point. A major application of this new paradigm is to produce materials with site-specific mechanical properties.

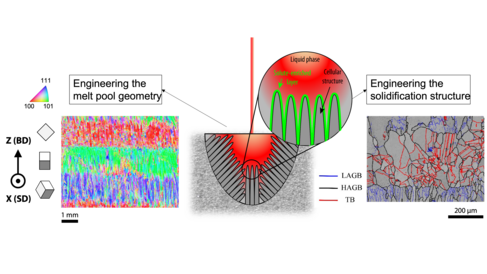

At the AddME Lab, we embrace this new metal design paradigm and devise non-conventional AM processing strategies to gain control over the above-mentioned microstructural features in steels and advanced nickel-base alloys. Our seminal work on "Layerwise Engineering of Grain Orientation (LEGO)", for instance, demonstrates how to achieve site-specific texture control in stainless steel 316L by engineering the thermal gradients within melt pools. Our LEGO strategy consists of keeping the laser scan angle constant throughout a certain number of layers to promote selective grain growth across adjacent melt pools. By changing the laser scan angle, we show that it is possible to grow (quasi) single crystal grains with controlled orientation throughout the build (see bottom left figure).

Another endeavour under the topic of site-specific microstructure control is that which focuses on engineering the grain boundary character distribution in 316L (see bottom right figure). Different papers we have published showcase the possibility of tuning the propensity of the alloy to undergo recrystallization; either using AM processes that integrate mechanical treatments, or by engineering the solidification structure of the material. Our perspective article discusses the new, exciting opportunities that this research may open up.

Work is ongoing to explore the possibility of site-specific phase control in multi-phase materials by acting upon melt pools cooling rates and the intrinsic heat treatment they induce in the surrounding material.